When sourcing stainless steel sheets for industrial, kitchenware, or furniture applications, quality inspection is critical. High-quality stainless steel sheets not only ensure better performance but also reduce processing risks and long-term costs. Therefore, understanding how to inspect stainless steel sheet quality helps buyers make more confident purchasing decisions.

1. Check the Surface Finish First

First of all, the surface condition is the most direct indicator of stainless steel sheet quality. A high-quality sheet should have a clean, uniform, and defect-free surface.

For example:

- 2B finish should appear smooth and consistent

- BA finish should show a bright, mirror-like surface

- No.4 or HL finishes should have even grinding lines

However, visible defects such as scratches, dents, oil stains, or uneven polishing may indicate poor handling or inconsistent processing.

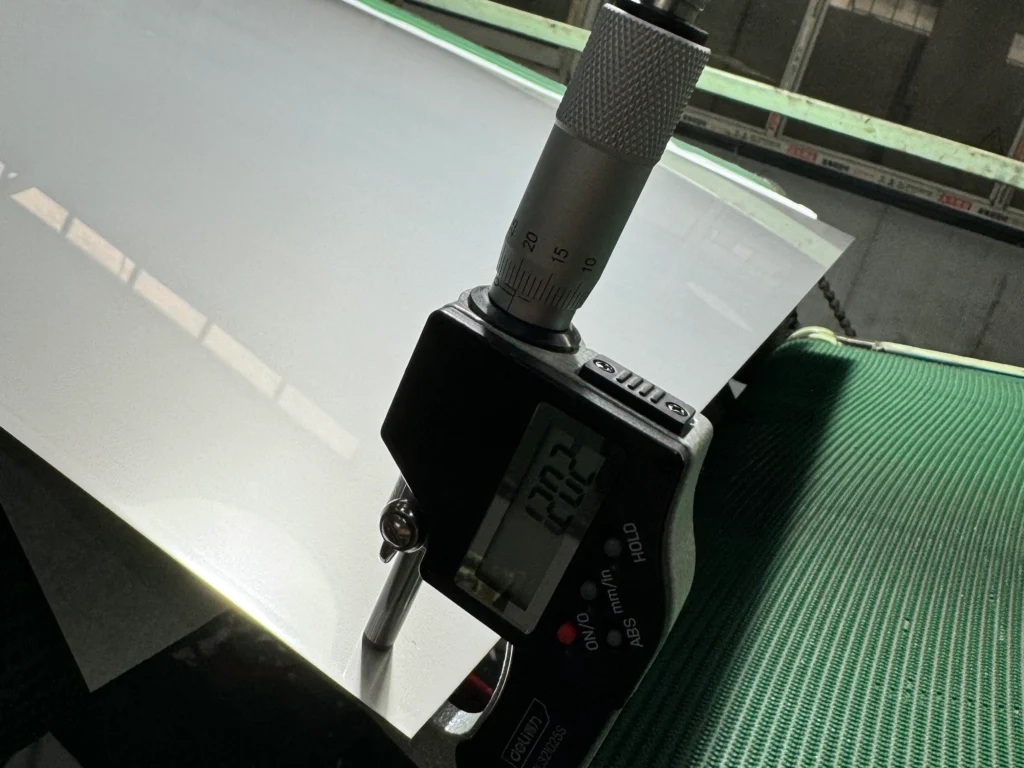

2. Verify Thickness and Flatness

Secondly, accurate thickness and flatness are essential for further fabrication. Reliable stainless steel sheet suppliers strictly control thickness tolerance according to international standards.

During inspection:

- Measure thickness using a micrometer at multiple points

- Check flatness by placing the sheet on a level surface

If thickness deviation is too large or the sheet shows obvious warping, it may cause problems during cutting, bending, or welding.

3. Confirm the Material Grade

In addition, confirming the correct material grade is a key step in quality inspection. Common grades include 201, 304, 316, and 430 stainless steel sheets, each suitable for different applications.

For instance:

- 304 stainless steel offers excellent corrosion resistance and is widely used in kitchen and furniture industries

- 316 stainless steel provides superior resistance to chemicals and marine environments

Therefore, always ensure the material grade matches your project requirements.

4. Review the Mill Test Certificate (MTC)

Moreover, professional stainless steel sheet suppliers usually provide a Mill Test Certificate (MTC, EN 10204 3.1) upon request. The MTC verifies chemical composition, mechanical properties, and production standards.

When reviewing the MTC, check:

- Heat number consistency

- Chemical composition compliance

- Mechanical test results

This document plays an important role in ensuring traceability and material reliability.

5. Inspect Edge Quality and Cutting Accuracy

Additionally, edge quality should not be overlooked. Well-processed stainless steel sheets have clean, burr-free edges, whether they are mill edges or cut-to-size sheets.

Poor edge finishing may affect safety, assembly accuracy, and final product appearance.

6. Evaluate Packaging and Protection

Finally, proper packaging reflects a supplier’s quality control awareness. High-quality stainless steel sheets are usually packed with:

- Protective PVC film

- Waterproof paper and strong pallets

- Secure strapping to prevent damage during transportation

Good packaging minimizes surface damage and ensures the sheets arrive in excellent condition.

Conclusion

In conclusion, inspecting stainless steel sheet quality involves more than a quick visual check. By carefully examining surface finish, thickness tolerance, material grade, documentation, edge quality, and packaging, buyers can significantly reduce sourcing risks.

Therefore, working with an experienced and reliable stainless steel sheet supplier is the best way to ensure consistent quality and smooth cooperation.

📩 Looking for high-quality stainless steel sheets with reliable inspection standards?

Feel free to contact us for specifications, samples, and export solutions.