Hot rolled stainless steel plates are widely used in industrial, construction, and manufacturing sectors due to their strength, versatility, and cost efficiency. Compared with cold rolled products, hot rolled plates are produced at high temperatures, which makes them ideal for applications where precise thickness tolerance is less critical but mechanical performance and durability are essential.

What Are Hot Rolled Stainless Steel Plates?

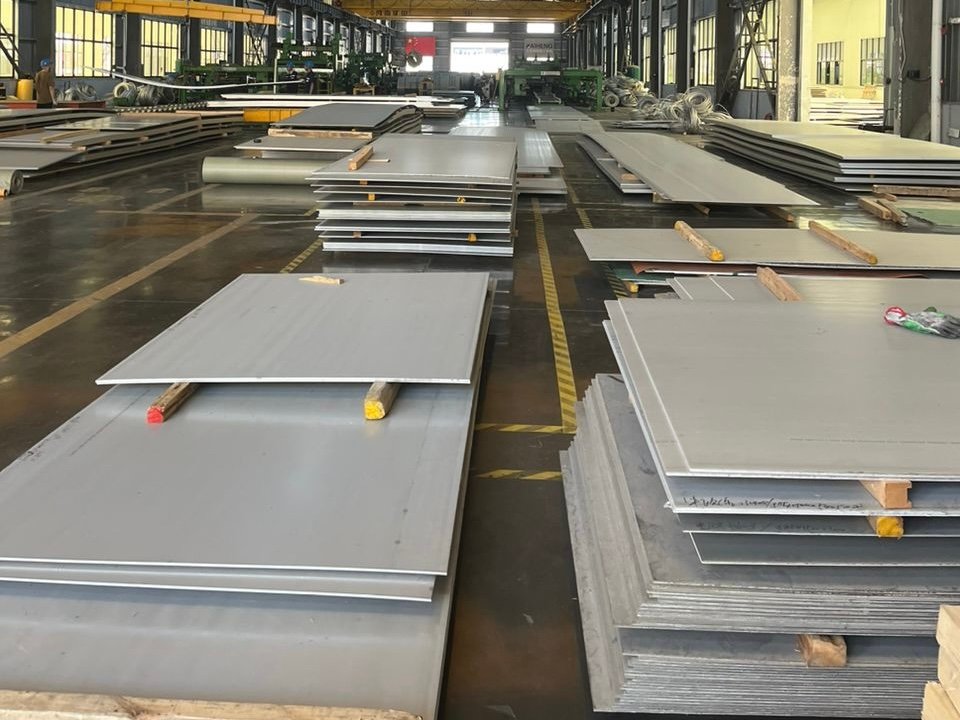

Hot rolled stainless steel plates are manufactured by rolling stainless steel slabs at temperatures above the recrystallization point. As a result, the steel becomes easier to shape and form. After rolling, the plates cool naturally, which leads to a slightly rough surface and wider thickness tolerance.

However, this process also improves structural integrity. Therefore, hot rolled plates are commonly selected for heavy-duty and load-bearing applications.

In many projects, hot rolled plates are used alongside stainless steel coils and stainless steel sheets to balance performance and cost.

Key Advantages of Hot Rolled Stainless Steel Plates

1. High Strength and Structural Stability

First of all, hot rolled stainless steel plates deliver excellent mechanical strength. They withstand heavy loads, impact, and pressure, which makes them suitable for demanding environments.

Moreover, their internal grain structure remains uniform, enhancing overall stability during fabrication and use.

2. Excellent Weldability and Fabrication Performance

Because hot rolled plates are processed at high temperatures, they show good weldability and formability. Consequently, cutting, bending, and welding operations become more efficient and cost-effective.

For fabrication workshops, combining stainless steel plates with stainless steel flat bars helps streamline production.

3. Cost-Effective Solution for Large Projects

Compared with cold rolled products, hot rolled stainless steel plates are generally more economical. Therefore, they are preferred for large-scale construction and industrial projects where surface finish is not the primary concern.

At the same time, they maintain corrosion resistance, which ensures long-term performance even in harsh environments.

Common Grades of Hot Rolled Stainless Steel Plates

The most widely used grades include:

- 304 / 304L – General-purpose grade with good corrosion resistance and formability

- 316 / 316L – Enhanced resistance to chemicals and marine environments

- 310S / 321 – High-temperature and specialized industrial applications

Depending on the application, these grades can be paired with stainless steel pipes or structural components for integrated solutions.

Typical Applications

Hot rolled stainless steel plates are used across multiple industries, including:

- Industrial equipment and machinery frames

- Construction and structural supports

- Pressure vessels and storage tanks

- Shipbuilding and offshore platforms

- Energy, chemical, and petrochemical plants

In many cases, engineers choose hot rolled plates for strength while using stainless steel sheets in areas where surface appearance matters more.

Hot Rolled vs Cold Rolled Stainless Steel Plates

Although both types serve important roles, their applications differ:

- Hot rolled plates prioritize strength, weldability, and cost efficiency

- Cold rolled plates focus on surface finish and tight dimensional tolerance

Therefore, selecting the right product depends on the specific project requirements rather than appearance alone.

Please follow us on Pinterest for more details.