Why Stainless Steel Is Safe for Food Contact

Stainless steel is one of the most widely used materials in food processing, commercial kitchens, and household cookware. From food-grade tanks to kitchen sinks and cutlery, it is trusted worldwide. But why exactly is stainless steel safe for food contact? Below, we explain the science, standards, and real-world benefits behind this material—and why it remains the first choice for food-related applications.

1. Non-Reactive and Chemically Stable

First and foremost, stainless steel is chemically stable. It does not react with food, even when exposed to acidic ingredients such as vinegar, citrus, tomatoes, or wine. As a result, it does not release harmful substances or alter taste, color, or aroma.

Thanks to its chromium content, stainless steel forms a passive oxide layer on the surface. This layer protects the metal from corrosion and prevents chemical interaction with food. Therefore, food safety remains consistent over long-term use.

In food production lines, materials such as stainless steel plates and stainless steel sheets are commonly used precisely because of this stability.

2. Excellent Corrosion Resistance

Another key reason stainless steel is food-safe lies in its corrosion resistance. Rust and corrosion can contaminate food and create hygiene risks. However, stainless steel resists rust even in humid, high-temperature, or salty environments.

Moreover, grades like 304 and 316 stainless steel offer enhanced resistance to moisture, acids, and cleaning chemicals. Consequently, they are widely used in food factories, breweries, dairies, and restaurants.

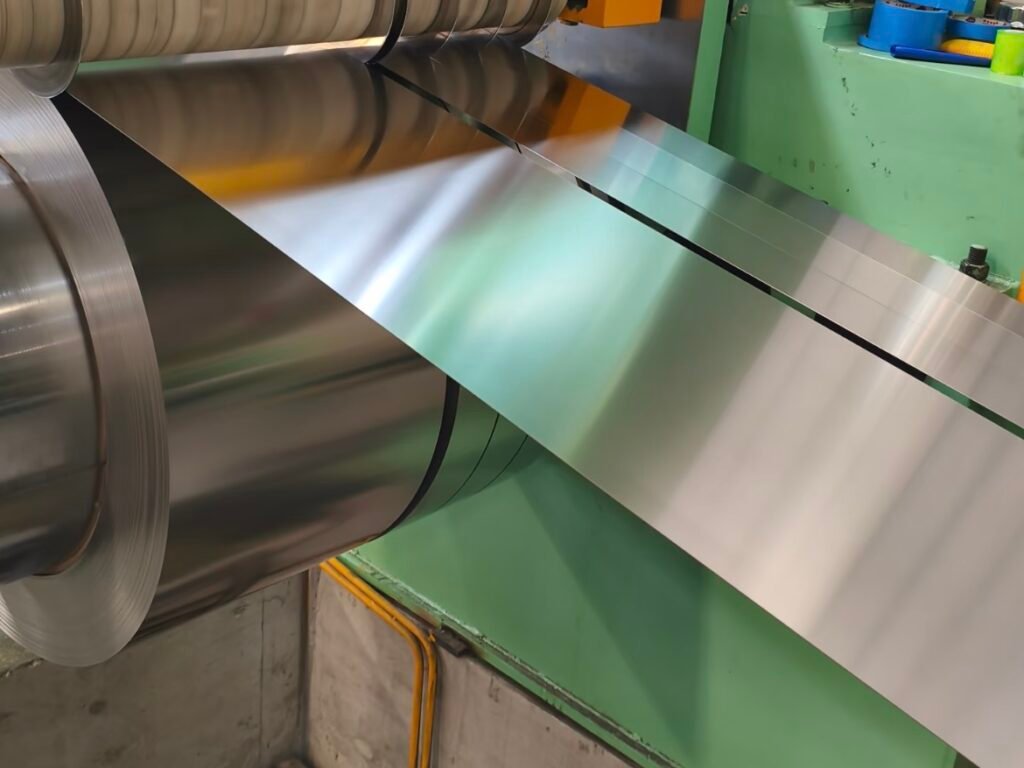

For applications requiring frequent washing or sterilization, stainless steel coils provide durability without compromising safety.

3. Easy to Clean and Highly Hygienic

Cleanability plays a crucial role in food safety. Stainless steel has a smooth, non-porous surface, which means bacteria, mold, and food residue are less likely to adhere.

In addition, stainless steel tolerates:

- High-temperature washing

- Steam cleaning

- Chemical disinfectants

As a result, it meets strict hygiene requirements in commercial kitchens and food-processing facilities. This is also why stainless steel pipes are widely used for food-grade fluid transport.

4. Complies with International Food Safety Standards

Stainless steel used for food contact complies with major international standards, including:

- FDA (U.S. Food and Drug Administration)

- EU food contact regulations

- LFGB (Germany)

These regulations confirm that stainless steel does not migrate harmful elements into food under normal conditions of use. Therefore, manufacturers and consumers can rely on its safety with confidence.

Food-grade equipment made from stainless steel flat bars and structural components is designed specifically to meet these compliance requirements.

5. Strong, Durable, and Long-Lasting

Durability also contributes indirectly to food safety. Stainless steel does not crack, chip, or degrade easily. Unlike coated or painted materials, it does not peel over time.

Because of its long service life, stainless steel reduces the risk of contamination caused by material breakdown. Additionally, fewer replacements mean lower long-term costs and more sustainable operations.

In industrial environments, stainless steel plates are often preferred for worktables and food contact surfaces due to their strength and reliability.

6. Heat Resistance Without Releasing Toxins

Stainless steel performs well under high temperatures. Whether used for cooking, baking, or sterilization, it remains stable and does not release toxic fumes or substances.

This makes it suitable for:

- Cookware and bakeware

- Food processing machinery

- Industrial ovens and heating systems

Compared with some plastics or coated metals, stainless steel maintains safety even under extreme heat.

Conclusion

In summary, stainless steel is safe for food contact because it is non-reactive, corrosion-resistant, hygienic, and compliant with global food safety standards. Furthermore, its durability and heat resistance make it a reliable long-term solution for both household and industrial food applications.

Whether you are choosing materials for commercial kitchens, food processing equipment, or storage systems, stainless steel sheets, stainless steel pipes, and stainless steel coils remain a proven and trusted choice for food safety.