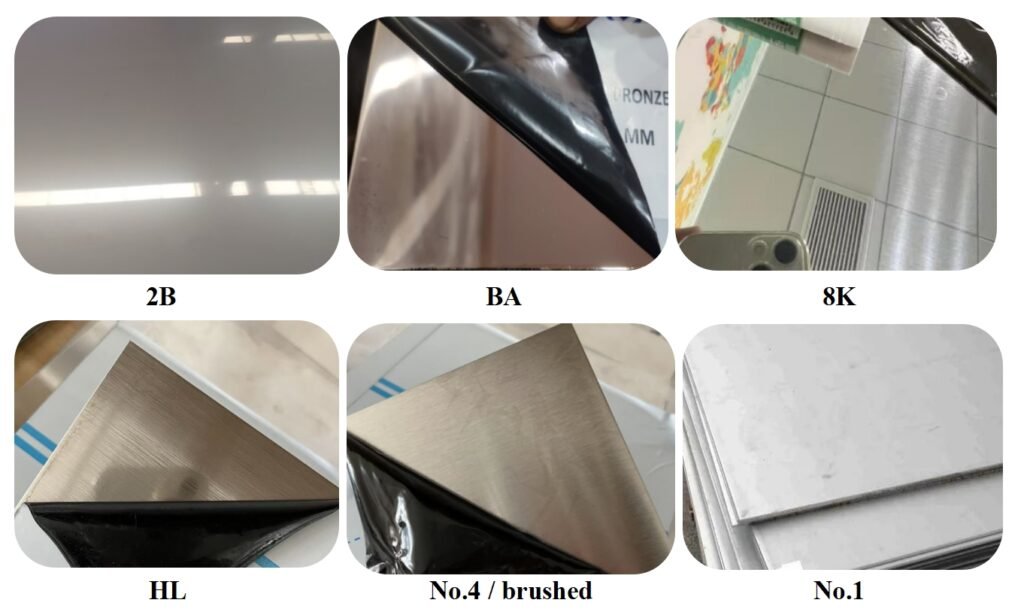

Stainless steel precision machined parts, especially stainless steel castings, often need to be polished. Stainless steel polishing can be roughly divided into two categories: brushed polishing and mirror polishing. These polishing also have different standards. The following is a brief introduction to the stainless steel polishing grades.

- 2B surface

The 2B treatment, also commonly known as “mill finish”, describes the treatment of the unpolished cold-rolled steel plate itself obtained from the production plant. It may sometimes show a slight sheen from the rolling process, but there is no reflection. - No.4 surface

After preliminary polishing, the final finish is achieved by polishing with a 120-180 grit abrasive belt. This special surface treatment is most commonly applied to 304 stainless steel and is used in a wide range of industries. - HL surface

This special surface treatment is often applied to stainless steel parts used in construction projects, such as glass clamps, stainless steel railings, etc. - BA surface

A highly reflective finish is achieved by polishing a surface. The surface of the part is carefully ground to achieve a mirror effect, but the sand lines are not removed by the final polishing process. This special finish is most commonly applied to 304 stainless steel and is used across a wide range of industries. - 8K Mirror

The 8K mirror finish is considered the industry standard for a highly reflective, mirror-like appearance. This is achieved by directional grinding with an abrasive in several stages, followed by buffing with a rouge oil. The resulting surface is bright, highly reflective, and virtually free of grit lines, although at certain angles some are still visible. This special finish is often used in elevators and escalators on a variety of metal types.

Pick the above image to follow us on Pinterest, learn more about stainless steel.